Wet batteries remain widely used across industrial, backup power, and energy storage applications. Compared with dry batteries, wet batteries rely on liquid electrolyte reactions, which makes their charging process inherently more dynamic. Understanding wet battery charging stages is essential for designing a reliable and safe battery charger.

A poorly controlled charging profile can accelerate electrolyte loss, cause excessive gassing, or permanently damage the battery plates. For this reason, wet battery chargers typically adopt a multi-stage charging strategy rather than a single fixed voltage or current mode.

In earlier discussions on dry battery charger voltage control , we focused on precision voltage stability. Wet batteries, however, require a more adaptive approach that balances voltage, current, and time across multiple charging stages.

Overview of Wet Battery Charging Stages

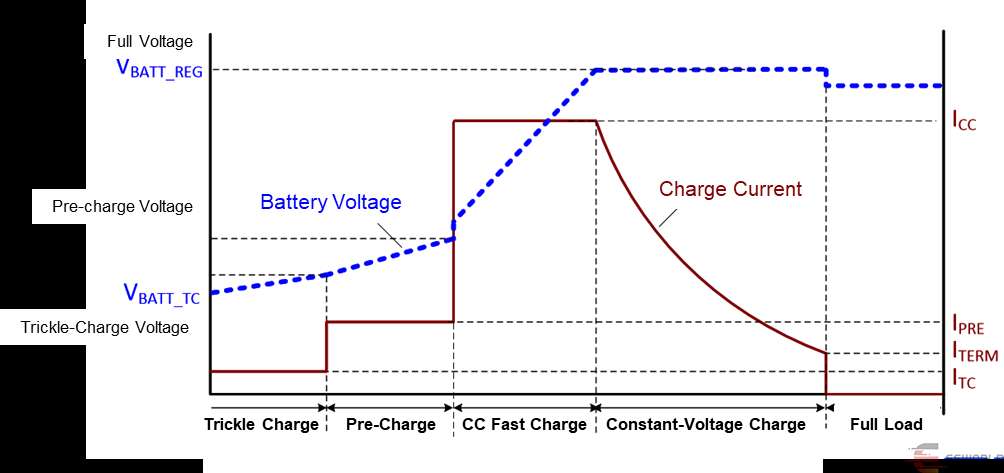

A typical wet battery charging process consists of several distinct stages, each serving a specific electrochemical purpose. These stages are designed to restore capacity efficiently while minimizing electrolyte degradation.

- Bulk Charging Stage

- Absorption Charging Stage

- Float Charging Stage

Each stage requires different voltage and current behavior, which is why charger firmware and control logic play a critical role in wet battery systems.

Bulk Charging Stage: Rapid Energy Replenishment

The bulk stage is the initial phase where the charger delivers maximum allowable current to the battery. During this phase, voltage gradually rises as the battery accepts charge. The primary objective is to restore the majority of the battery’s capacity as quickly as possible.

From a charger design perspective, this stage emphasizes current regulation. Voltage is monitored closely, but current remains the dominant control variable. Once voltage approaches a predefined threshold, the charger transitions to the next stage.

For engineers designing programmable charging systems, our reference on multi-stage battery charger design explains how current limits and transition thresholds are implemented in real-world products.

Absorption Charging Stage: Controlled Voltage Holding

The absorption stage is where voltage regulation becomes critical. The charger maintains a constant voltage while allowing current to gradually taper off as the battery approaches full charge. This phase ensures deep charging without excessive gassing.

Poorly tuned absorption voltage can cause overheating or electrolyte loss, particularly in high-capacity wet batteries. This is why absorption parameters often vary depending on battery chemistry, plate construction, and intended application.

According to the technical overview on lead-acid battery charging behavior , the absorption stage plays a decisive role in balancing charging speed with long-term battery health.

Float Charging Stage: Maintaining Battery Readiness

Once the battery reaches near-full capacity, the charger enters the float stage. Voltage is reduced to a safe maintenance level that compensates for self-discharge without triggering further chemical reactions.

Float charging is especially important for standby power systems, where batteries may remain connected to a charger for extended periods. In such cases, even minor voltage drift can have cumulative effects over time.

To address this, modern battery chargers often incorporate temperature compensation and adaptive voltage adjustment, ensuring stable long-term operation across varying environmental conditions.

Why Charging Stages Matter in Wet Battery Charger Design

Unlike dry battery systems, wet batteries require a charging strategy that actively responds to electrochemical changes throughout the process. This makes charging stage control a defining feature of any wet battery charger.

For OEM manufacturers, selecting or designing a charger with proper stage sequencing reduces maintenance costs, improves safety margins, and extends battery service life.

If your application involves different wet battery formats or capacities, charger flexibility becomes even more important. Stage parameters must be configurable rather than fixed.

Transitioning Toward Sealed and Dry Battery Systems

As energy storage technologies evolve, many systems are transitioning from traditional wet batteries to sealed or dry alternatives. This shift introduces new requirements for charging control and monitoring.

In the next article, we will explore how sealed battery chargers differ from wet battery chargers, and why sealing fundamentally changes voltage tolerance and charging strategy.