Smart Power Tool Battery Charger & BMS: From User Pain Points to Engineering Practice

As power tool batteries push higher in voltage and capacity, robust safety and intelligent management have become critical. This article integrates global user feedback and recent research to provide engineering-grade guidance for charger and BMS design.

We examine multi-layer safety architecture, precise SOC/SOH estimation, predictive health strategies, and system-level authentication—all realized in a cohesive solution by Phonix Charger.

1. Real User Pain Points: Key Technical Challenges

- SOC Estimation Accuracy: Voltage-based methods often drift under partial discharge. Traditional equivalent circuit models (ECM) may fail to maintain accuracy, impacting operational efficiency.

- BMS vs Charger Roles: The BMS protects cells, while the charger governs strategy. Float charging, if unmanaged, keeps cells at high voltage, accelerating aging.

- Thermal Runaway Risk at High SOC: High SOC amplifies thermal failure risk. Without predictive detection, cell failure can escalate rapidly.

- SOH Estimation Reliability: Sudden SOH drops highlight the limits of simple internal-resistance or cycle-count models.

2. Multi‑Layered Safety Architecture

BMS: The Control Center

A functional BMS includes:

- Real-time monitoring of individual cell voltage, current, and temperature.

- State estimation: SOC, SOH, remaining useful life (RUL).

- Cell balancing: Passive or active methods to equalize cell charge.

- Thermal management: Heating/cooling control to maintain safe operating conditions.

- Communication with the charger or other systems for diagnostic data.

Hardware Architectures

- Centralized BMS: One controller monitors all cells—cost-effective for power-tool packs.

- Modular BMS: Multiple modules monitor subsets of cells—scalable.

- Distributed BMS: Controllers on individual cells—robust and fault-tolerant.

Predictive Safety Mechanisms

- Data-driven fault classification: Machine learning models predict thermal failures before escalation. See IEEE / arXiv Thermal Modeling.

- Multi-sensor fusion: Voltage, temperature, and gas sensors (e.g., H₂) provide early warning.

- Redundant safety circuits: Primary and backup layers reduce single-point risk.

3. Intelligent SOC / SOH Estimation

Method Comparison

| Method | Principle | Strengths | Constraints | Use Case |

|---|---|---|---|---|

| Equivalent Circuit Model | RC network simulation | Mature, moderate computation | Model drift over time | Embedded MCU platforms |

| Online Impedance | Real-time EIS | High accuracy (~3%) | Hardware intensive | High-end Li-ion Battery Packs |

| Digital Twin | Cloud virtual battery | Adaptive, accurate | Requires cloud connectivity | Connected smart BMS |

| Deep Learning | Feature extraction + state estimation | High accuracy, predictive | Requires large dataset | Next-gen BMS |

Digital Twin & Cloud Integration

Using a digital twin, a BMS can perform real-time SOC/SOH estimation through cloud data synchronization. Studies confirm improved estimation stability. See IEEE Digital Twin SOC/SOH.

Predictive Health Management (PHM)

PHM uses reliability models to proactively guide charging and balancing, ensuring BMS adapts to aging and maintains safety over the battery lifecycle.

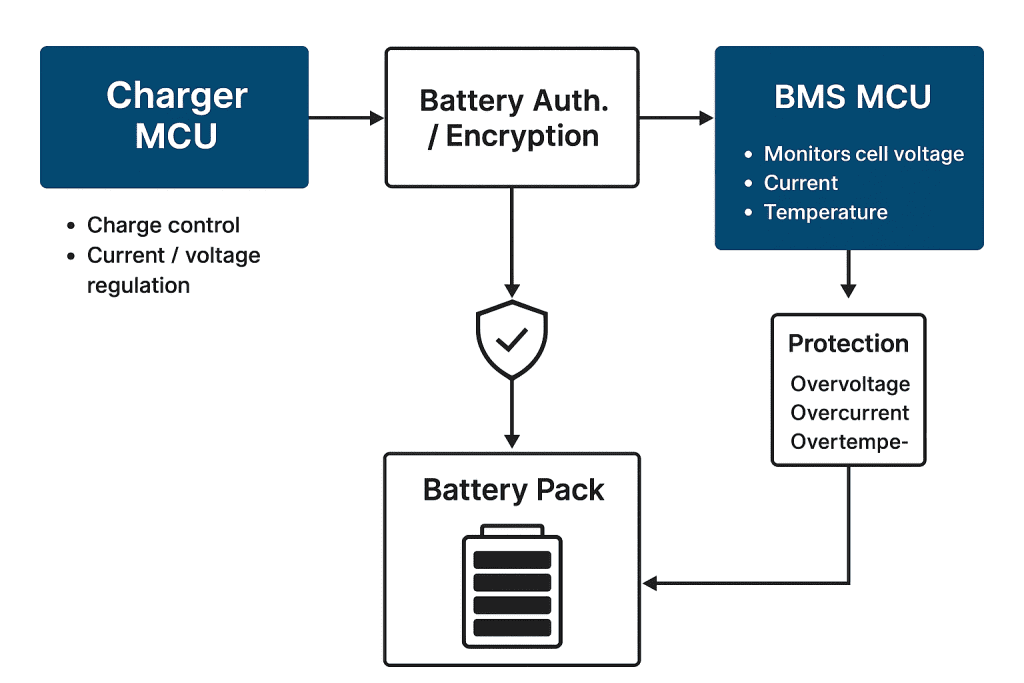

4. Engineering Practice: Phonix Charger System Architecture

Phonix Charger integrates advanced safety, state estimation, and management:

Smart BMS & Charger Coordination

- High-precision SOC/SOH via ECM + online parameter identification.

- Individual cell monitoring and active balancing at charge termination.

- Adaptive charging based on SOH estimation.

- OTA-capable firmware for continuous improvement.

Protection Framework

- Hardware protection: Over-voltage, over-current, over-temperature circuits.

- Algorithmic protection: Predictive thermal models.

- Redundant protection: Multi-layer circuits.

Battery Authentication

- Internal resistance / EIS fingerprinting for validation.

- Mutual authentication protocol between BMS and charger.

- Unverified battery charge refusal; anti-tamper protections.

5. Smart Battery Evolution: Sensing → Dynamic Response → Autonomous Decision

- Generation 1 – Real-time Sensing: Monitors voltage, current, temperature.

- Generation 2 – Dynamic Response: Uses SOH for adaptive charging and balancing.

- Generation 3 – Autonomous Decision: Combines digital twin + AI for predictive control.

Phonix Charger aligns with this evolution, helping engineers move from sensing to predictive and autonomous decision-making.

6. Regulatory & Safety Standards

BMS and battery packs must conform to global standards: IEC 62133 safety standard, and LCIE Bureau Veritas BMS compliance.