AI+ BMS Future Charging Management System :BMS will become more automated, AI management will make it easier for users to use battery products safely, and charging will also be safer.

I’m Changan, leading BMS R&D at Phonix. Every day, I talk to customers frustrated with battery problems—some with EVs stranded mid-route, others seeing home storage batteries degrade too quickly, making ROI calculations a nightmare. It became clear: half the value of a battery lies in the cells themselves, and the other half is hidden in the “brain” that manages them—the Battery Management System (BMS).

Have you ever been stressed by sudden fleet battery drops? Or wondered why two identical batteries can have vastly different lifespans? Traditional maintenance often feels like a gamble, with unexpected downtime disrupting operations. The result: wasted battery value and rising costs.

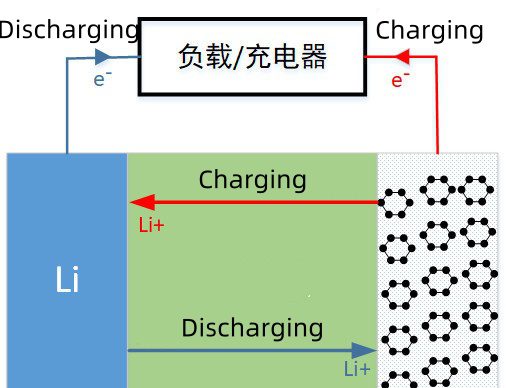

Traditional BMS acts like a diligent gatekeeper, monitoring voltage, current, and temperature. If anything exceeds thresholds, it immediately cuts power. Safe, yes—but reactive. It can’t answer questions like:

- “This battery seems fine now, but will it fail next month?”

- “Why do other fleets get two more years out of the same battery model?”

- “Which units really need maintenance, and when?”

At Phonix, we pair the gatekeeper with an experienced AI strategist.

This AI “advisor” can read subtle signals in charging and discharging curves, spotting issues weeks before they become critical. It gently balances cells before serious divergence occurs, keeping the battery pack in harmony and extending lifespan. It recognizes patterns that suggest a unit might fail in the near future, allowing maintenance to be scheduled in advance instead of reacting after the fact.

Importantly, the AI only advises. All safety-critical actions remain firmly in hardware hands. This system has been rigorously tested and complies with international safety standards such as IEC 62619. Every AI decision carries a confidence score: if confidence is below 90%, control reverts to traditional BMS logic, ensuring seamless, risk-free operation.

The real-world impact is clear. A European shared EV fleet struggled with frequent battery failures, leading to stranded vehicles and customer complaints. After deploying Phonix AI BMS, the system flagged 15% of high-risk batteries in advance. Replacing them reduced roadside failures by 40% within a month. Vehicles ran reliably, users were happier, and operations teams finally got some rest.

Similarly, an Asian home energy storage user wanted to profit from peak/off-peak electricity pricing but worried about battery degradation. Our AI analyzed their usage patterns, automatically scheduling the most cost-effective and battery-friendly charge/discharge cycles. The outcome: 15% more savings on electricity bills and a 20% increase in expected battery lifespan.

From these examples, it’s clear: a smart BMS doesn’t just protect batteries—it turns them into valuable assets. Every optimization is grounded in hardware safety rules and algorithmic foresight, minimizing risk and making operations predictable.

Behind the scenes, our AI models have been co-validated with global OEMs across thousands of cycles and diverse conditions. All actions are rate-limited and double-checked, and the system supports instant rollback to any stable version. Smart optimization happens entirely within a safe boundary—you can rely on it completely.

If you want to avoid sudden battery failures, maximize the lifespan of every unit, and make your operations transparent and predictable, now is the time to act. Learn more about Phonix BMS solutions, or contact us to get a customized Battery Health & Efficiency Optimization Plan for your operations.

For deeper technical understanding, you can also refer to the Battery Management System article on Wikipedia.