You design a high-power custom battery charger by scaling the power architecture, current control strategy, and thermal management together, instead of simply increasing output wattage.

High-power battery chargers do not fail because of voltage errors. Instead, they fail due to poor current distribution, thermal overload, and unstable control loops. Therefore, designing chargers from 10W up to 3000W requires a structured, system-level approach.

Why Power Scaling Is Not Linear

A 3000W charger is not a larger version of a 300W charger. As power increases, switching losses, magnetic saturation, and thermal stress grow exponentially. Because of this, engineers must redesign topology, not merely increase component ratings.

Industry references such as the Texas Instruments power management design resources explain how efficiency and thermal behaviour shift dramatically at higher power levels.

Topology Selection Across Power Ranges

At low power levels (10W–100W), flyback or buck-derived topologies are usually sufficient. However, once power exceeds several hundred watts, these designs become inefficient and thermally unstable.

For mid-power ranges (300W–1000W), LLC resonant converters or phase-shifted full bridges become more suitable. Beyond 1500W, designers often adopt multi-phase or interleaved architectures to distribute current evenly.

Thermal Design as a Core Constraint

Thermal design defines the upper power limit of any charger. Rather than treating heat dissipation as an afterthought, professional designs consider airflow, conduction paths, and component spacing from the beginning.

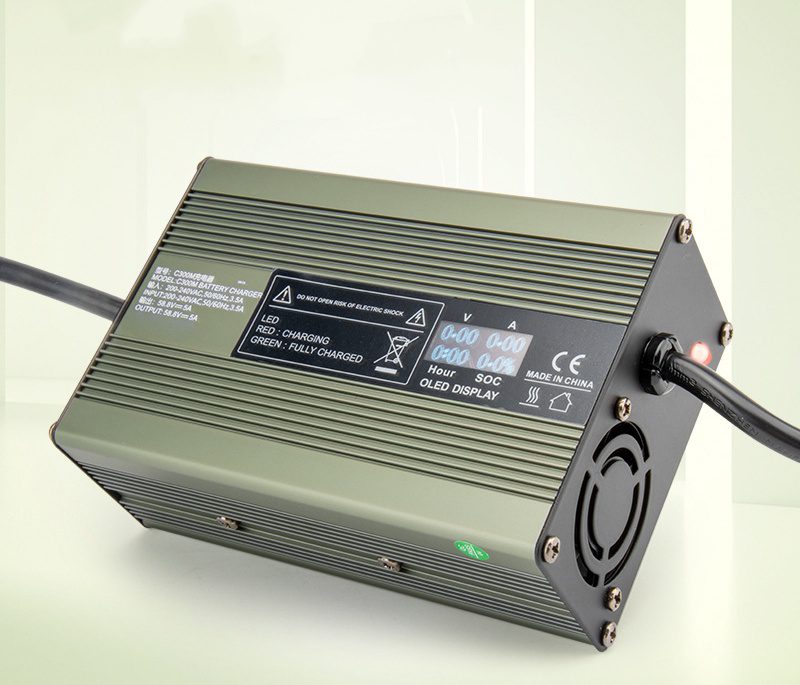

A custom battery charger developed for high-power operation often integrates temperature feedback into its control firmware. As a result, the charger dynamically reduces output when thermal thresholds approach critical limits.

Current Control and Battery Protection

As power increases, current control accuracy becomes more critical. High current amplifies the risk of connector heating, cable loss, and battery stress. Therefore, precise current sensing and fast feedback loops are mandatory.

Standards such as IEC safety frameworks for power electronics provide guidance on current handling, isolation, and fault protection in high-power systems.

Integration with BMS and System Logic

In high-power systems, the charger must respond immediately to BMS feedback. Without communication, even a minor battery fault can escalate rapidly.

By integrating digital communication, the charger adjusts current limits, pauses charging, or shuts down safely. This approach mirrors the architecture used in BMS-integrated charging systems for energy storage and industrial equipment.

Conclusion

Designing a high-power custom battery charger from 10W to 3000W requires architectural decisions, not incremental scaling. By aligning topology, thermal management, and current control, engineers create chargers that remain stable, efficient, and safe across wide operating ranges.