You differentiate 18650 and 21700 battery chargers in custom industrial designs by aligning current limits, thermal management, and voltage control to the specific cell format and pack configuration, rather than reusing a one-size-fits-all solution.

In industrial battery systems, two cylindrical lithium formats dominate: 18650 cells and 21700 cells. Although both share similar chemistry, they differ significantly in physical size, energy density, internal resistance, and heat generation. Therefore, charger designs for each format must reflect these differences at a fundamental engineering level.

Key Differences Between 18650 and 21700 Battery

lithium battery charger comparison 18650 and 21700

industrial battery charger with BMS integration

thermal management for cylindrical lithium chargers

At their core, 21700 cells offer higher capacity and better energy density compared to 18650 cells. Because of this, 21700 packs typically require higher current delivery and enhanced thermal control. In contrast, 18650 packs often prioritise balanced current distribution and finer voltage regulation.

Both cell types are widely used in electric vehicles, energy storage, and industrial systems, as documented in technical resources such as the Battery University overview of lithium battery cell formats. This source explains how different cylindrical formats impact performance, thermal behaviour, and safety considerations.

Current Scaling and Design Implications

When designing a charger for 18650 battery packs, engineers usually emphasise precise current limiting and voltage control. 18650 cells, due to their smaller size, generate heat more rapidly under high current. Therefore, chargers often implement refined current tapering during the constant-current (CC) phase to prevent thermal stress.

By contrast, 21700 packs typically operate at higher current levels without the same rapid heat rise, but they still demand robust thermal monitoring. As a result, a custom battery charger for 21700 systems often includes enhanced heat dissipation features and current scaling logic.

Voltage Precision and Pack Configuration

The voltage per cell remains similar for both formats, but pack configurations and series counts differ. For example, a 10S configuration using 18650 cells may differ slightly in voltage ripple and internal resistance compared to a similarly configured 21700 pack. Therefore, charger voltage sensing and feedback loops must be tuned accordingly.

Moreover, industry standards such as the IEEE 1725 standard for rechargeable batteries provide guidance on safety, testing, and design safety goals for portable lithium cells. Although targeted originally at consumer devices, the safety principles remain relevant for larger format packs in custom industrial chargers.

Thermal Management Strategies

Thermal behaviour directly influences charger design. In 18650 packs, the smaller size and tighter cell spacing can lead to hotspots when current rises. Consequently, engineers often rely on more aggressive current tapering during the CC/CV phases and more frequent temperature sampling.

Conversely, 21700 packs, by virtue of their larger form factor, distribute heat differently and allow slightly higher sustained current before thermal protections engage. However, without appropriate thermal management, both formats risk accelerated aging and safety derating.

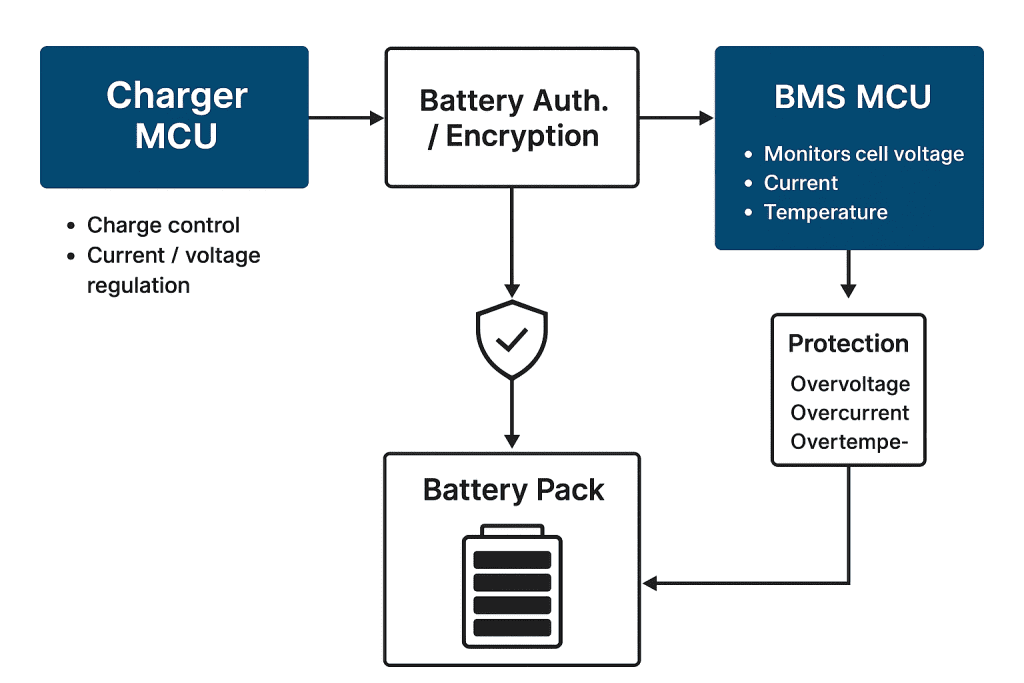

Integration with BMS and System Communication

Modern custom battery chargers almost always integrate with a Battery Management System (BMS) to enhance safety, longevity, and efficiency. Through communication protocols such as CAN, UART, or RS485, the BMS provides real-time cell voltage and thermal data, enabling the charger to adjust current limits or cut off charging when necessary.

This system-level coordination appears in a range of industrial applications, from automated guided vehicles to energy storage racks, and matches practices used in BMS-integrated charger solutions.

Design Testing and Qualification

Once the charger hardware and firmware logic align with target cell formats, engineers must validate performance across a battery of tests. Thermal cycling, voltage accuracy evaluation, and fault injection tests help ensure safe operation under industrial workloads.

In addition, compliance with safety frameworks like IEC 62660 (for lithium-ion battery performance) ensures that charger behaviour meets internationally recognised performance expectations. Such frameworks guide test methods and help align chargers with global deployment needs.

Conclusion: Matching Charger Design to Cell Format

The fundamental difference between 18650 and 21700 battery chargers lies in how designers balance current control, voltage precision, and thermal strategy according to actual cell behaviour. By integrating the charger with the BMS and tuning parameters to match each format, engineers build systems that perform reliably in demanding industrial and energy storage environments.

In summary, a successful custom charger design does not treat 18650 and 21700 formats interchangeably. Instead, it acknowledges their unique characteristics and adapts current limits, feedback logic, and protection thresholds accordingly.