An industrial lead-acid charger is designed around fundamentally different charging logic and protection principles compared to lithium battery chargers. Understanding these differences is critical for engineers selecting charging solutions for industrial power equipment and energy storage systems.

1. Battery Chemistry and Charging Behavior

Lead-acid batteries are sensitive to over-voltage, prolonged high-current charging, and temperature variations. As a result, industrial lead-acid charger design relies on controlled charging stages to prevent sulfation and excessive gassing.

Lithium batteries operate under a different electrochemical model. They require strict voltage limits and current tapering but do not support continuous float charging in the same way as lead-acid systems.

2. Industrial Lead-Acid Charger Charging Architecture

An industrial lead-acid charger typically implements a multi-stage charging process, including bulk, absorption, and float stages. Each stage is designed to balance charging efficiency with long-term battery health.

These charging principles align with widely accepted lead-acid battery charging methodologies described in international IEC battery charging guidelines.

3. Voltage Regulation and Power Range Considerations

From a system design perspective, industrial lead-acid chargers are often engineered to support wide voltage ranges, commonly from 6V up to 84V, and power levels from tens of watts to several kilowatts.

Lithium chargers, by comparison, are usually optimized for narrower voltage windows matched to specific battery configurations, prioritizing precision over flexibility.

4. Safety and Protection Strategy

An industrial lead-acid charger integrates multiple protection mechanisms, including over-voltage protection, reverse polarity protection, thermal shutdown, and time-based safety limits.

Lithium charging systems depend more heavily on coordinated protection between the charger and the battery management system to ensure cell-level safety.

5. System-Level Integration in Industrial Applications

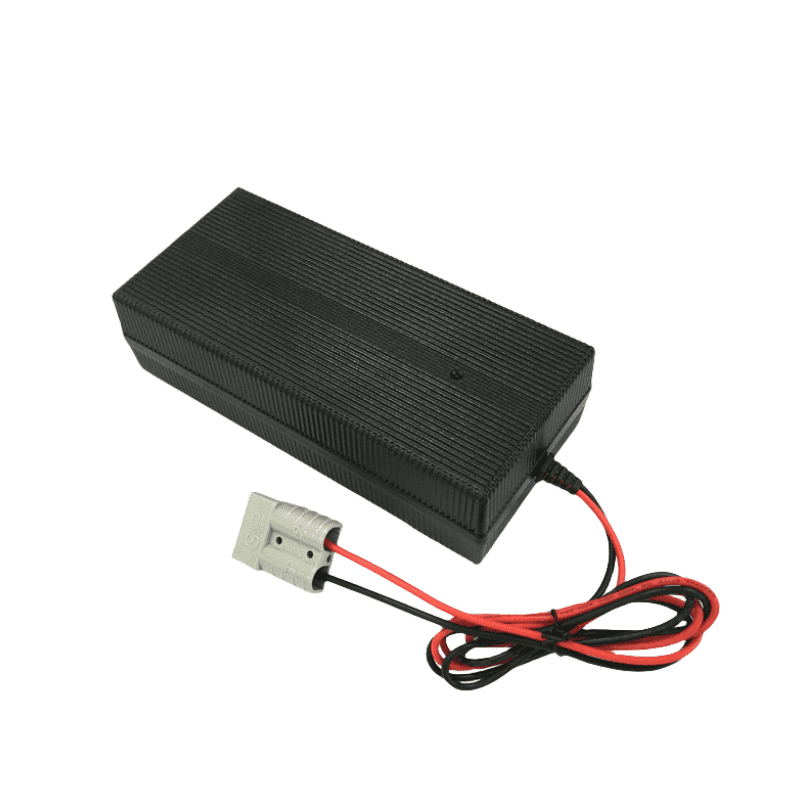

Industrial lead-acid chargers are commonly deployed in backup power systems, industrial power equipment, and stationary energy storage installations where robustness and service life are prioritized.

For projects requiring deeper system integration, customized charging solutions are often developed to align charger behavior with overall power management architecture.

Conclusion: Selecting the Appropriate Charger Technology

While lithium charging technology offers advantages in energy density, an industrial lead-acid charger remains a reliable and proven solution for many industrial systems due to its tolerance, predictable behavior, and mature charging methodology.

The correct charger selection should be driven by battery chemistry, operating environment, and system-level reliability requirements rather than market trends.