Custom Smart battery charger specialist

In many OEM and industrial projects, battery chargers are often treated as standard accessories.

As long as the voltage and current appear correct, the charger is expected to “just work”.

In practice, however, charging performance has a direct impact on battery safety, system stability, certification outcomes, and long-term product reliability.

This is why more OEM teams are shifting their focus toward working with a custom battery charger manufacturer rather than relying on off-the-shelf solutions.

Customization Goes Beyond Electrical Parameters

Voltage and current are only the starting point of a charger design.

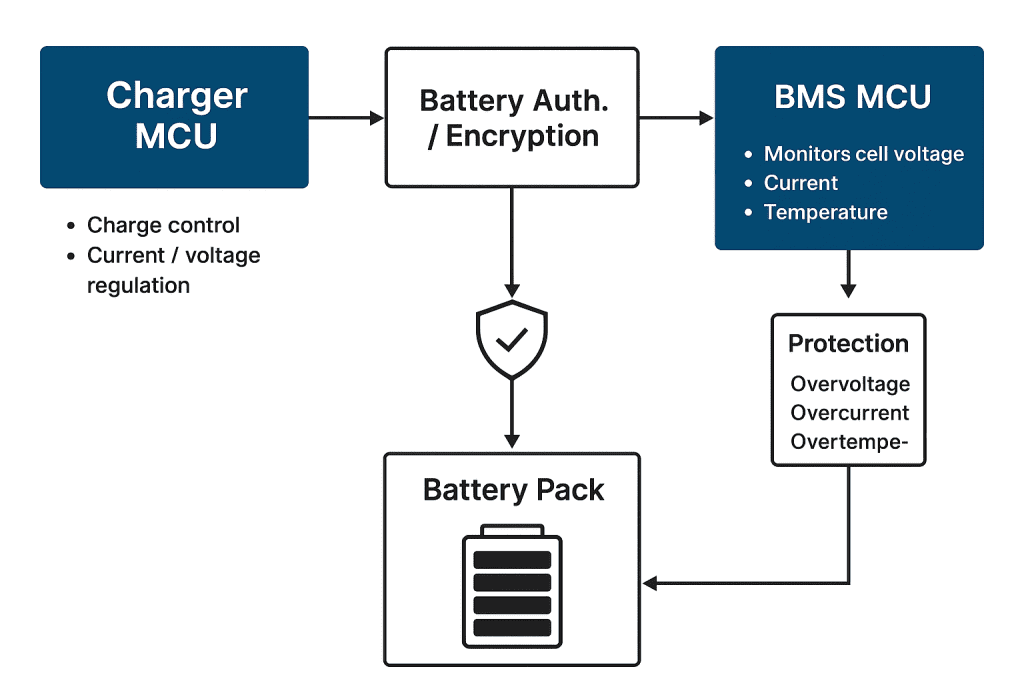

Real-world customization typically involves battery chemistry behavior, charge termination logic, thermal management, protection coordination with the BMS, and how the charger interacts with the host system under different operating conditions.

For many projects, these requirements cannot be addressed by catalog products.

They require an engineering-driven approach, where the charger is developed as part of the system rather than added at the end.

This philosophy is reflected across Phonix’s battery charger product portfolio, which is structured around application needs instead of generic power ratings.

Engineering-Led Design Reduces Integration Risk

A custom charger is not simply a modified power supply.

Early engineering decisions — such as topology selection, component stress margins, charging algorithm tuning, and certification strategy — determine whether a charger will perform reliably over its entire lifecycle.

OEM buyers who involve a charger engineering team early in the process are far less likely to face unexpected redesigns, certification delays, or thermal issues during mass production.

This is especially relevant for energy storage systems, industrial power equipment, smart mobility products, and AIoT devices, where the charger must operate consistently under demanding conditions.

Customization Also Means Long-Term Stability

Another reason OEM buyers choose custom solutions is long-term stability.

Beyond meeting today’s specifications, a charger design must remain manufacturable, support controlled updates, and adapt to future product iterations without introducing risk.

For this reason, many OEM projects eventually move toward customized charger solutions that are engineered with supply continuity and lifecycle management in mind.

When Does a Custom Charger Make Sense?

A custom smart charger is worth considering when:

- The battery configuration is non-standard

- Safety and certification margins are critical

- Charger–BMS interaction affects system behavior

- Product longevity and scalability matter

If your project falls into these categories, engaging an engineering-focused supplier early can significantly reduce total development cost and risk.

To explore your requirements from a technical perspective, you can contact our engineering team to discuss how a custom charger approach may support your product roadmap.